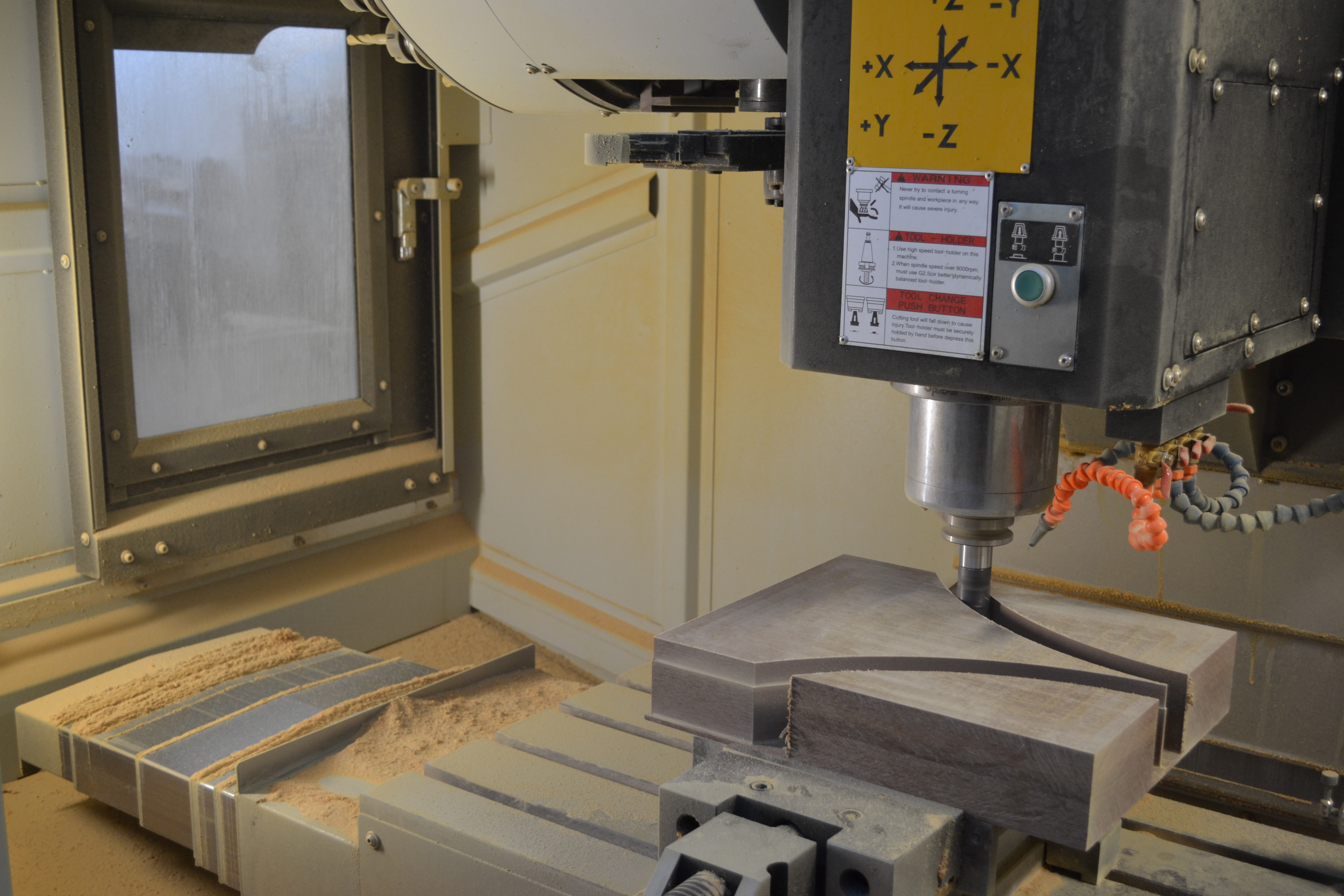

CNC is an abbreviation for "Computer Numerical Control". CNC is a production method using computer technology and automation. In this method, thanks to a computer program, machines can automatically process a specific design and produce parts.

CNC machining offers many advantages over traditional manual machining methods. Operations such as cutting, drilling, grinding and milling of the workpiece can be carried out with precision and repeatability. CNC machines require less manpower thanks to automation and provide faster and more efficient production.

CNC machines can generally be 3-axis, 4-axis or 5-axis. While 3-axis CNC machines can move in the X, Y and Z axes, 4- and 5-axis machines additionally have the ability to make rotational movements. Therefore, 4- and 5-axis machines are preferred for the production of complex and precise parts.

CNC usage areas are quite wide and are especially widely used in industrial production. CNC machines play an important role in many industries such as metal processing, wood processing, plastic processing, automotive, aerospace, medical devices and electronics. CNC technology offers the opportunity to make production processes more flexible and innovative while increasing efficiency.

The foundations of Hermetal Makina were laid in 1975 by K. Solmaz Boral Öndün and Gökhan Öndün in Topkapı, Istanbul.[...]

When you visit our website, your personal data is processed in accordance with the legislation. To read the information textclick here.

While some cookies on our website work to present the content on our website, other cookies work to measure your use of our website, and the processing of your personal data with these cookies is subject to your express consent. You can provide your explicit consent with "I Accept", not with "I Do Not Accept", or you can save your options in Cookie Preferences. To read the information text regarding your personal data that will be processed with cookies click here.